While larger model basins can be found in Finland, Sweden, and Denmark, the facility in Saaremaa serves a vital niche – it conducts tests on smaller working vessels up to 40 metres in length.

Laboratory head Ruttar Teär explains that the small craft segment requires particular attention, as large model testing basins often do not prioritise smaller vessels in their schedules. “Our clear advantages are shorter waiting times and a precise focus on smaller vessels, since larger centres frequently lack the time or interest to accommodate them,” he emphasised.

The laboratory offers a wide range of services to shipbuilding companies, from computational simulations to complex experimental trials. The main goal is to optimise the design and engine power of small craft to achieve maximum energy efficiency. “We contribute to the green transition in small craft construction by helping to avoid oversized engines – this ultimately results in a smaller ecological footprint and greater economic savings.”

“We contribute to the green transition in small craft construction by helping to avoid oversized engines – this ultimately results in a smaller ecological footprint and greater economic savings.”

From model to reality

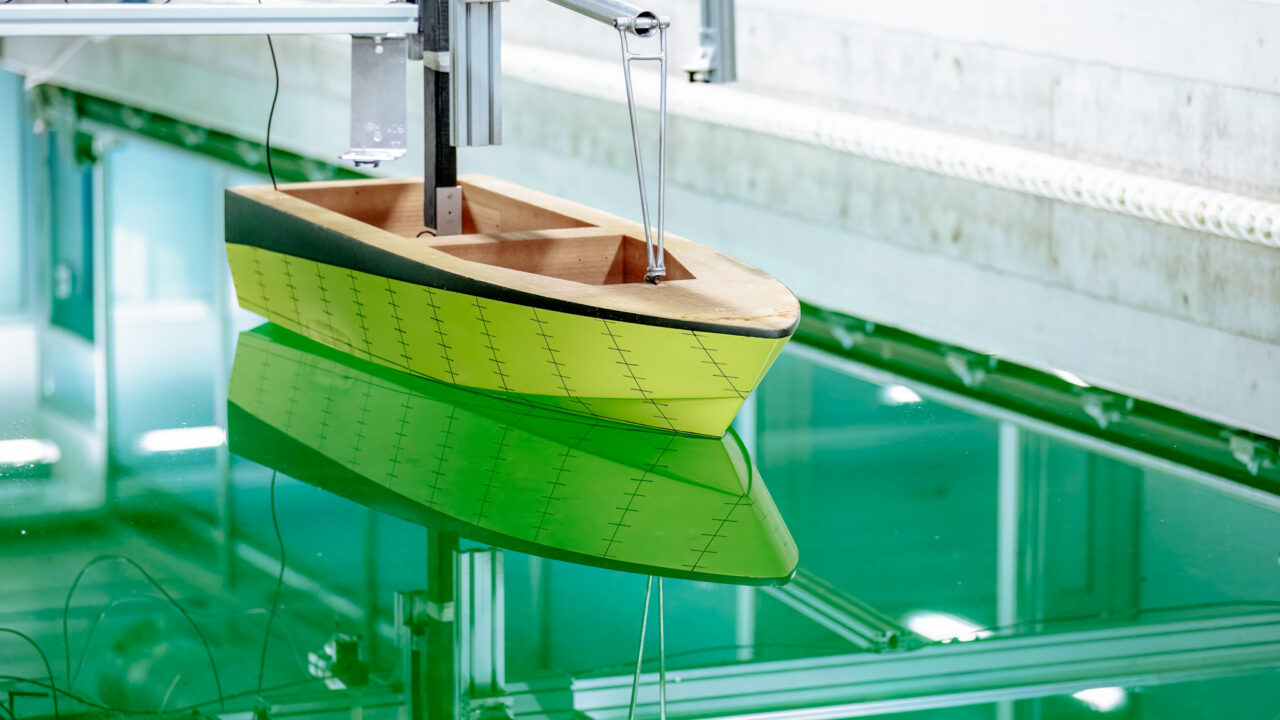

Everything begins with engineering work, as model creation is a complex process requiring a high level of technical precision and attention to detail at every stage.

First, the client sends the laboratory a digital design model, which undergoes thorough verification and validation. If it meets all criteria, the production of the blank begins, using a special CNC milling process – a computer-controlled method for cutting and shaping metal or other materials – carried out by local companies.

The process then continues in the laboratory, where the models are assembled by hand. To ensure the models closely match real vessels in terms of centre of gravity and balance, materials such as Divinycell foam, aluminium and 3D printing are used.

Once the model is complete, it undergoes precise weighing and balancing. “This can take two to three weeks – it requires great accuracy and care to adjust the model’s total mass and moment of inertia,” Teär explained. Only then can the water trials begin.

Saving lives starts with model testing

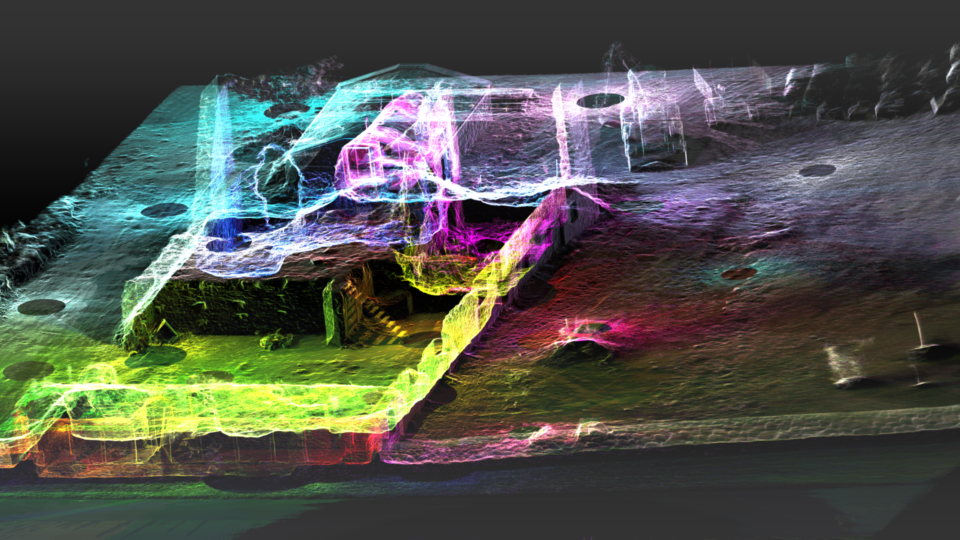

In April, the laboratory is carrying out a unique test in collaboration with Baltic Workboats. Never before have such complex scenarios been simulated in the model basin. “Usually, we test how a vessel handles obstacles and waves, but this time we’re replicating a capsizing situation – and investigating whether the vessel can right itself in a critical emergency,” Teär explains.

The need for the test arises from a real-life incident in which a coastal rescue boat capsized during a storm. Water flooded the wheelhouse, leading to tragic consequences. To prevent such accidents in the future, Baltic Workboats is developing a new vessel with one key requirement: reliable and rapid self-righting ability.

For the test, a scaled-down but structurally accurate model was built, including the superstructure. It will be flipped upside down in the basin, and researchers will observe how quickly and in what manner the model rights itself and drains the water. According to Teär, the test is technically challenging due to various variables – for instance, it is difficult to determine an appropriate timescale, since the movement of water cannot be scaled down proportionally.

This kind of testing provides designers and manufacturers with the critical data needed to build vessels capable of recovering quickly and safely in life-threatening situations. “Model testing allows us to ensure that the final vessel will not endanger the crew or equipment in a crisis,” Teär emphasised.

“Model testing allows us to ensure that the final vessel will not endanger the crew or equipment in a crisis.”

In April, the lab is testing for the first time – in collaboration with Baltic Workboats – whether a capsized vessel can right itself in a critical situation. Photo: Age Teär

A reborn maritime nation

In a broader context, Kuressaare College Marine technology competence centre is helping Estonia evolve into a true maritime nation. For a long time, Estonia was more of a coastal country, with its maritime activity stalling during the occupation period – but now the nation is on a path of recovery and renewal. Teär notes that the modern testing capabilities being developed at the college – including the model testing laboratory – are part of a larger effort to revitalise Estonia’s maritime culture and shipbuilding expertise.

In addition to hands-on engineering work, Kuressaare College offers advanced computational simulations, marine environment modelling, and the ability to conduct open-water experiments. This comprehensive approach provides companies with critical data in less time and at a lower cost compared to full-scale testing.

The college’s work shows that the future of Estonian maritime affairs lies not only in new ships and ports, but in smart and responsible solutions. “Our tests represent just one part of a bigger picture – a framework in which we create new opportunities while ensuring safety and environmental stewardship. That’s how we become a true maritime nation,” said Teär.

“Our tests represent just one part of a bigger picture – a framework in which we create new opportunities while ensuring safety and environmental stewardship. That’s how we become a true maritime nation.”

Teär noted that the modern testing capabilities being developed at the college – including the model testing lab – are part of a broader effort to revive Estonia’s maritime culture and shipbuilding skills. Photo: Karl-Kristjan Nigesen

Comment: Martin Kalmet, project manager at Baltic Workboats

According to Martin Kalmet, project manager at Baltic Workboats, the company’s collaboration with the hydrodynamics laboratory at Kuressaare College has been smooth and effective. In April, he commissioned a self-righting test from the lab, which also included an assessment of the wheelhouse drainage system. Baltic Workboats has made use of the lab’s services before.

Kalmet sees the laboratory’s greatest strength in its flexibility – the ability to make swift changes on-site during testing and to shift direction if necessary. This is precisely why the current test is being conducted in Kuressaare. The services are also reasonably priced, and Baltic Workboats’ own team can be actively involved in the process. “Because we didn’t know exactly what the outcome would be, the most important thing was knowing that if something didn’t work, we could quickly adapt and find a solution,” Kalvet explained.

The lab’s technical capabilities and test results have been of real value to the company – they’ve helped to confirm assumptions that computational models alone couldn’t fully verify. This has, in turn, provided the project team with a level of confidence that would otherwise have been lacking.

Kalmet says they hope to continue the collaboration in the future, depending on market direction. He recommends the lab’s services especially to companies that lack specific expertise in certain areas, or for whom it wouldn’t be practical to maintain the necessary equipment and specialists in-house.