Random start

It all started modestly, when lecturer Ago Roots posed a question in the hallway that would transform the team’s entire learning experience: “Would you be interested in building a machine for a company?” The answer was a resounding yes, but the first setback followed quickly – the idea initially failed to secure funding. Some time later, a new opportunity arose through the AIRE programme, and the team seized it, eventually receiving support that allowed them to move forward with the project.

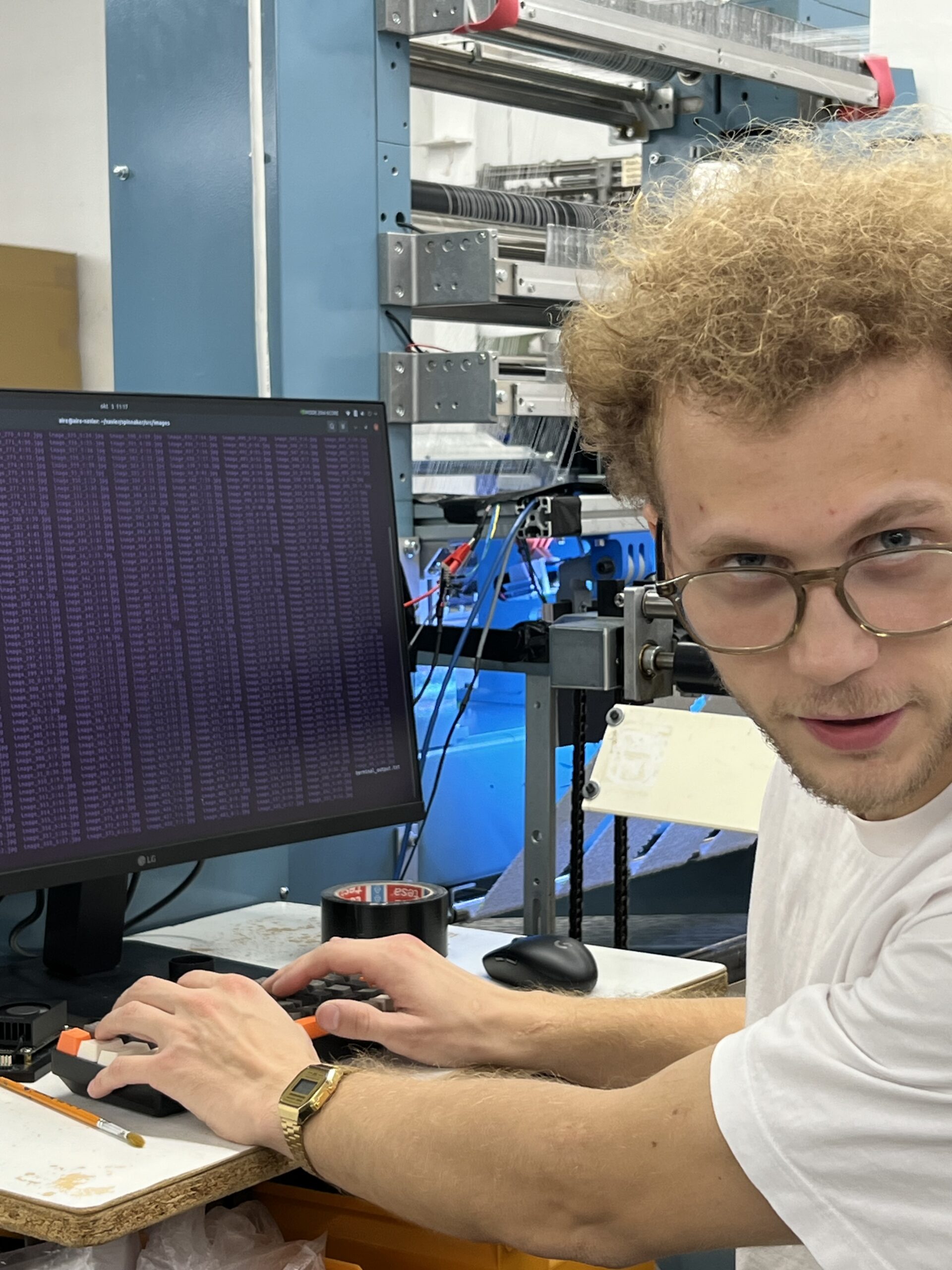

In the final phase, the team’s machine learning specialist Gregor Kokk began developing the model. Using hundreds of image samples, the algorithm was trained to distinguish between correct patterns and those indicating defects. The process required constant fine-tuning and experimentation – and often involved tackling issues that had never come up in a classroom setting.

Photo: TalTech

Both students and industry partners come out as winners

The outcome of the project was a camera- and machine learning–based system that monitors production on two lines simultaneously, detects potential defects, and displays their exact location on screen. To simplify the workflow, the system provides precise information about which line and where the issue has occurred, allowing factory staff to respond quickly and correct the errors.

Yet the value of the project went far beyond the technological solution. The students learned how to take an idea from concept to completion, how to communicate with industrial partners, and how to divide responsibilities and roles within a team. For many, it was the first encounter with real clients and real-world expectations. This hands-on experience gave them both confidence and the opportunity to tackle real-life problems.

The project stands as a clear example of how involving students in solving real-world challenges can benefit all parties – young professionals gain experience and self-assurance, while companies receive fresh, innovative solutions. The three ingredients of success – the use of a lab model, on-site work in the factory, and persistent effort – show that the road from theory to practice begins with curiosity and leads to innovation.