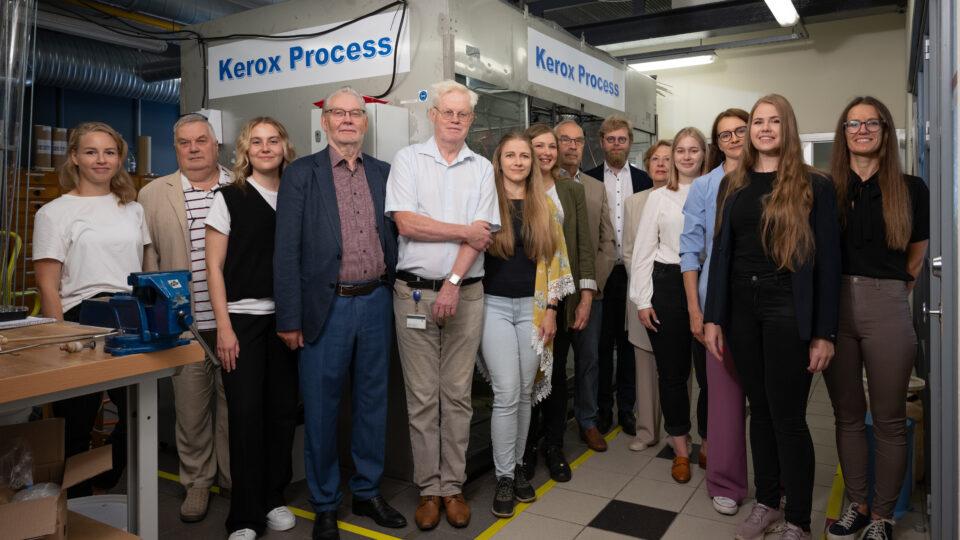

TalTech senior researcher of Chemistry and Biotechnology department Yevgen Karpichev and from his sustainable chemistry and engineering team early-stage researcher Mahendra Kothottil Mohan, deeply involved in lignin valorization research, shed light on the growing importance of this biopolymer and its vast industrial potential.

Lignin, a complex aromatic biopolymer, is produced in massive quantities—around 75 million tons per year—largely as a byproduct of the pulp and paper industry, but also from other biomass sources. Historically, it has been primarily used as a low-value fuel source, burned for energy. However, researchers are now pioneering ways to chemically modify lignin to create materials with superior properties and higher economic value.

Lignin is the only biopolymer that contains aromatic molecules, making it unique. „It has a big future, Our research is focused on functionalizing lignin for a range of applications, including bioplastics, pharmaceuticals, and fuels, among other high-value products,“ says Karpichev.

“It has a big future, Our research is focused on functionalizing lignin for a range of applications, including bioplastics, pharmaceuticals, and fuels, among other high-value products.”

Mohan adds that the goal is to explore how lignin-derived alternatives could replace expensive and non-renewable fossil-based chemicals, making sustainable materials more affordable. „For instance, in our recent studies, we demonstrated how lignin can be incorporated into bioplastics, reducing both production costs and environmental impact.“

Lignin is a complex aromatic biopolymer that is produced in vast quantities every year – approximately 75 million tons – mainly as a byproduct of the pulp and paper industry, but also from other biomass sources. Photo: Unsplash

Advancing lignin applications: from bioplastics to 3D printing

The drive toward a circular bioeconomy is one of the main forces behind the growing interest in lignin. Utilizing biomass-based raw materials inherently supports carbon neutrality and reduces dependency on fossil resources. “By default, using bio-based materials decarbonizes the economy. Plants absorb carbon dioxide during growth, making lignin an inherently renewable resource,” explains Karpichev.

Moreover, lignin-based materials have the potential to significantly lower production costs. “For example, lactic acid-based bioplastics are already available on the market but are relatively expensive to and produced from starch, which competes with the food supply chain. If we integrate lignin, which is an abundant and cheap material, we can make these sustainable nonfood-based bioplastics more affordable and accessible,“ Mohan notes.

Despite the benefits, replacing fossil-based materials with lignin-derived alternatives remains a challenge as fossil-based plastics are cheaper and often have superior mechanical properties. “However, our research aims to enhance the mechanical strength of lignin-based plastics so they can compete with traditional materials. In addition, lignin helps to reduce costs and improve sustainability,“ Mohan acknowledges.

“However, our research aims to enhance the mechanical strength of lignin-based plastics so they can compete with traditional materials. In addition, lignin helps to reduce costs and improve sustainability.”

Lignin’s unique properties, including its resistance to heat and mechanical stress, make it a valuable candidate for applications beyond bioplastics. „Our research into 3D printing composites with high lignin content has shown potential, particularly in thermal resistance. However, further development and testing are needed before commercialization,” adds Karpichev.

Technological innovations in lignin valorization

Karpichev noted one of the key objectives is depolymerization—breaking down lignin into smaller molecules that can serve as precursors for fuels, pharmaceuticals, and specialty chemicals. “We also work closely with biochemical researchers who investigate enzyme-driven depolymerization, aiming for a more sustainable and efficient process, “ explains Karpichev.

This approach is not limited to lignin valorization alone. Researchers are also exploring the reverse process—creating lignin-like materials from bio-waste streams, which could open new avenues in sustainable material production.

The field of lignin research has evolved significantly over the last two decades. “Twenty years ago, studies focused on basic properties like melting points. Now, we are developing market-oriented materials with advanced functionalities,” says Karpichev.

“Twenty years ago, studies focused on basic properties like melting points. Now, we are developing market-oriented materials with advanced functionalities.”

Promising applications include bioplastics for reducing reliance on petroleum-based plastics, medical uses such as wound dressings and drug delivery systems, cosmetics like hydrogels and bio-based skincare products, sustainable aviation fuels as an alternative to fossil fuels, and high-performance 3D printing materials with improved thermal properties.

Yevgen Karpichev, a senior researcher at the TalTech Department of Chemistry and Biotechnology, said that the unique properties of lignin, such as heat resistance and mechanical durability, make it valuable even beyond the field of bioplastics. Photo: Aivo Kallas

Addressing lignin’s hurdles: variability, scalability, and color

Despite its potential, according to Mohan, lignin presents significant challenges in industrial applications. Unlike conventional polymers, the lignin does not have a uniform chemical structure. This variability makes it difficult to create standardized products. Additionally, the dark brown color of lignin can limit its use in certain industries, such as cosmetics and packaging.

Another major hurdle is scalability. For lignin-based products to compete with fossil-based alternatives, large-scale production needs to be cost-effective and energy-efficient.

Looking ahead, researchers are optimistic about the role lignin will play in the bioeconomy. “The next big step is controlled depolymerization—finding efficient ways to break down lignin into high-value small molecules for use in fuel and pharmaceuticals. We are also exploring biochemical methods that could allow us to fine-tune lignin structures at the molecular level,“ says Karpichev.

Mohan believes that while research in lignin-based products is advancing, it may take 5 to 10 years to achieve major improvements that could make them more competitive with fossil-based materials. “With continued advancements, lignin could become a key player in sustainable material development, reducing our dependence on non-renewable resources.”

“With continued advancements, lignin could become a key player in sustainable material development, reducing our dependence on non-renewable resources.”

Lignin valorization is more than just a scientific challenge, it represents a critical step toward a greener, more sustainable future. As researchers refine the chemistry and technology behind lignin-based materials, industries will have access to innovative solutions that reduce environmental impact and support the transition to a circular bioeconomy.