On April 2, experts, researchers, and entrepreneurs gathered at TalTech’s Circular Economy Core Laboratory’s annual conference “Resources in Circulation” to discuss how the use of secondary raw materials, innovative technologies, and effective policy measures can help shape a more sustainable economy.

The conference shifted the focus from traditional waste management to a fundamental question: where should circulation truly begin – at the point of waste generation or at the point of raw material demand? Discussions highlighted the need to change the existing waste narrative and start planning resource use based on the logic of economic demand for raw materials.

The global political situation demands rapid adaptation

In his opening speech, Tiit Land, Rector of TalTech, emphasized that the university has something to offer society every single day. He highlighted the development of the Circular Economy Core Laboratory since its establishment in 2022 into a collaboration platform that now connects researchers, students, and international partners, supporting both research and practical education. According to Land, it is a “bottom-up” initiative where knowledge and solutions meet to help transfer research results into Estonia’s economy and industry.

Tarmo Kalvet, Professor of Sustainable Value Chain Management Unit at TalTech, noted in his presentation that the global free trade model, which developed after World War II, is under unprecedented pressure. The COVID-19 crisis revealed just how vulnerable international supply chains are, and recent U.S. trade policies have further intensified the situation. Under President Trump’s administration, U.S. tariffs surged sharply, particularly targeting Brazil, Russia, India, and China (known as the BRICS bloc), but the changes have also affected Europe.

According to Kalvet, three distinct global power blocs are emerging: BRICS and its allies, who are strengthening ties with resource-rich countries in Latin America and Africa; the European Union, which aims to reduce dependency on single suppliers; and the United States, which, besides confronting BRICS, is increasingly at odds with the EU as well.

An analysis of Estonia’s import dependency revealed that although many goods are imported from geopolitically friendly countries, Estonia remains heavily reliant on China and other BRICS allies for critical materials. “Especially in the electronics industry and raw materials, Estonia depends significantly on geopolitically distant suppliers,” Kalvet pointed out.

Kalvet urged companies and researchers to collaborate more closely to mitigate supply chain risks and expand export opportunities. He stressed that promoting circular economy practices and industrial symbiosis is a key strategy to enhance economic resilience. The shifting geopolitical and trade landscape demands swift adaptability from both companies and countries – securing supply chains and finding new markets are becoming increasingly vital.

In his presentation, Tarmo Kalvet, Professor of Sustainable Value Chain Management at TalTech, stated that the global free trade model established after World War II is under unprecedented pressure. Photo: Arno Mikkor

Circulating raw materials – the road to strategic autonomy

In a panel discussion led by Rutt Hints, Senior Researcher at TalTech, participants explored whether the circular economy could become the lifeline for Europe’s economy.

Martin Triipan, attorney-at-law at Ellex Raidla law firm, emphasized that traditional legal frameworks tend to treat waste more as a problem than as an opportunity. The use of secondary raw materials is often hindered by complex and burdensome regulations, increasing the administrative load. “Because using secondary materials requires carrying out complex environmental impact assessments and applying for permits, many businesses prefer the simpler route of using primary raw materials,” Triipan noted.

Tõnu Tuppits, Head of the Mineral Resources and Secondary Raw Materials focus area at the Estonian Business and Innovation Agency, pointed out that although nearly 8,000 companies in Estonia operate with circular economy business models, the share of firms developing secondary raw material usage remains marginal. “Neighboring countries have moved toward implementing circular economy action plans, while in Estonia it is still primarily associated with waste management,” Tuppits said. He also noted the lack of targeted measures to support the handling of industrial and mining waste, which limits the sector’s development.

Paavo Pettai, Marketing and Communications Manager at Trisector OÜ, added that an industrial shift has taken place in Estonia in recent years, creating a strong foundation for the circular economy. However, when companies enter the secondary raw material market, they encounter numerous barriers – from restrictive standards to regulations that hinder innovation. “The circular economy can only develop if it is built on an economic model that creates real value. If entrepreneurs do not see the benefits, technologies will not be developed,” Pettai emphasized.

Paavo Pettai, Marketing and Communications Manager at Trisector OÜ, added that an industrial shift in recent years has created a strong foundation for the circular economy in Estonia. Photo: Arno Mikkor

The discussion also raised the question of whether promoting the circular economy should be considered as important as strengthening national defense. Professor Riina Aav, head of SOURCES – the Estonian Centre of Excellence for Circular Economy based at TalTech – pointed out that these areas are not in conflict but rather complement each other. “Even in the defense sector, large amounts of reusable materials are generated – even uniforms need to be recycled,” she noted.

The panel emphasized the need to make the regulatory environment more flexible – to speed up environmental assessments and permitting processes and to deploy digital solutions, including artificial intelligence, to reduce administrative burdens. The sector also needs government support to create a more attractive investment environment for the circular economy.

The participants agreed that advancing the circular economy requires a systematic, cross-sectoral approach, focusing on the broader use of secondary raw materials and enhancing the resilience and strategic autonomy of Estonia’s economy.

Rutt Hints. Photo: Arno Mikkor

The journey of textiles and plastics into circulation

The second discussion, “From Problem to Solution – Circularity of Textiles and Plastics,” focused on the challenges and opportunities related to the collection, sorting, and recycling of two complex waste streams: textiles and plastics.

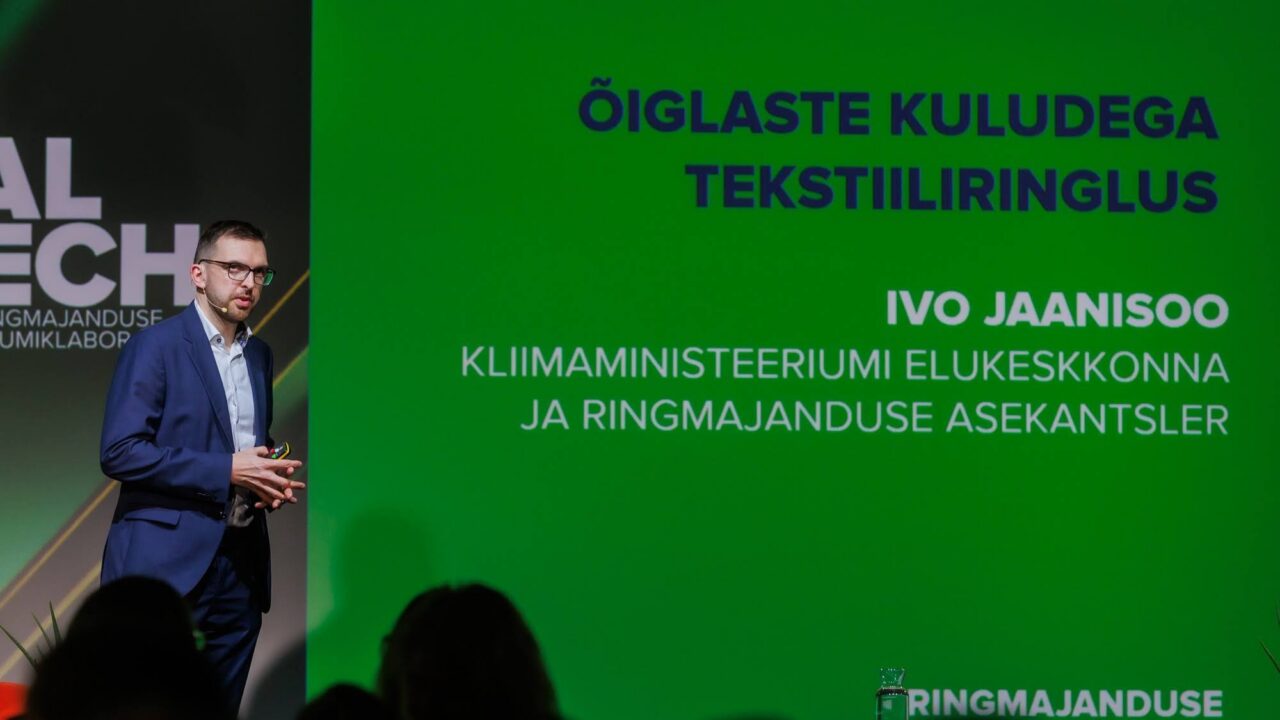

In the keynote speech preceding the panel, Ivo Jaanisoo, Deputy Secretary General for Living Environment and Circular Economy at the Ministry of Climate, highlighted that recycling plastics and textiles is particularly challenging because these are not pure materials but rather composites, which complicates their processing. In Estonia, approximately 20,000 tonnes of textile waste are generated annually, yet only about 5,000 tonnes are collected for reuse.

Another major issue is that separately collected waste is often poorly recycled, and when it is, the associated costs are very high. As a solution, Estonia plans to implement the principle of extended producer responsibility by 2028 at the latest, requiring producers to manage the waste generated from their products.

Progress has been made in plastic recycling – the collection system for packaging waste and the producer responsibility scheme are working, and over 90% of deposit packaging is recovered from the market. However, more complex packaging materials, such as meat trays and yogurt cups, remain problematic and often end up in nature or landfills.

Ivo Jaanisoo, Deputy Secretary General for Living Environment and Circular Economy at the Ministry of Climate, noted that recycling plastics and textiles is challenging because they are not pure materials but composites, which makes them harder to process. Photo: Arno Mikkor

The panel discussion, moderated by Professor Tiia Plamus, Head of TalTech’s Textile Technology Laboratory, featured Ivo Jaanisoo, Professor Andres Krumme, Head of TalTech’s Biopolymer Technology Laboratory, Ilo Rannu from Neular OÜ, and Kerli Kant Hvass, founder of Revaluate OÜ and Associate Professor at Aalborg University.

Experts agreed that the biggest obstacles to recycling plastics and textiles are the complex composition of the materials and the very low market readiness. “There is still a lot of confusion and greenwashing in the plastics sector – fossil-based plastics account for about 95% of the market,” Krumme noted. According to him, bio-based plastics have potential, but their broader adoption requires strong political and economic pressure.

Hvass explained that the global textile recycling rate is only 0.3%, meaning that the vast majority of textile waste is not being reused. “We need to create a system that steers production towards recyclable products and encourages companies to invest in new technologies. Estonia has the opportunity to carve out a niche in the global circular textile system, but this requires a deliberate and long-term strategy,” she emphasized.

According to Rannu, the economic model for recycling plastics and textiles is difficult, and without state support, the practice is currently not viable. “The circular economy is expensive and requires strong support schemes. Mechanical recycling remains the most viable route, but it too demands substantial investments,” he added.

During the discussion, participants concluded that further progress requires greater producer responsibility and increased consumer awareness. Estonia must invest in preprocessing capabilities to divert more materials into circulation and build a functioning and reliable producer responsibility system. “We must look beyond immediate problems and create a comprehensive system that motivates both companies and consumers to participate actively in recycling,” Jaanisoo stressed.

The future of plastics and textile waste recycling largely depends on political decisions, technological advances, and society’s readiness to consume and produce more sustainably.

The panel discussion, moderated by Professor Tiia Plamus, Head of TalTech’s Textile Technology Laboratory, included Ivo Jaanisoo, Professor Andres Krumme, Head of TalTech’s Biopolymer Technology Laboratory, Ilo Rannu from Neular OÜ, and Kerli Kant Hvass, founder of Revaluate OÜ and Associate Professor at Aalborg University. Photo: Arno Mikkor

Wood awaits new solutions beyond burning

TalTech professor and ÄIO Tech co-founder Petri-Jaan Lahtvee raised a “burning” question: should we continue burning wood, or should we find better ways to utilize it? His presentation introduced a panel discussion on the opportunities and challenges of adding value to low-quality wood.

Lahtvee emphasized that Estonia ranks among the top five countries in the world with the largest resource consumption footprint – if the entire world consumed resources at Estonia’s pace, the annual limit of natural resources would be exhausted by early March. Such a consumption model is unsustainable and urgently needs change.

According to him, one of the key solutions lies in the advancement of biotechnology and the promotion of the bioeconomy. Researchers at TalTech’s bioengineering lab are working with microorganisms that can convert low-value raw materials, such as wood waste and CO₂, into high-value-added chemicals and materials.

For example, ÄIO Tech is developing wood sugar–based fats and oils that can be used in the food industry and cosmetics. According to a McKinsey report, synthetic biology could have a significant impact on the global economy by 2040 – up to $0.8 trillion in consumer products and $0.3 trillion in the medical sector.

Petri-Jaan Lahtvee emphasized that Estonia ranks among the top five countries in the world in terms of resource consumption footprint – if the whole world consumed resources at Estonia’s pace, the annual limit of natural resources would be exhausted by early March. Photo: Arno Mikkor

In the joint discussion, Jaanus Uiga, Deputy Secretary General for Energy and Mineral Resources at the Ministry of Climate, highlighted that wood is used in a variety of ways in Estonia – from household firewood to district heating and electricity production. Although wood is an important fuel for district heating, increasing renovation efforts and the addition of new heat sources are intensifying competition for low-quality wood. This, in turn, may direct more wood into higher value-added utilization projects.

According to Alar Konist, Director of TalTech’s Department of Energy Technology, it is also necessary to consider hydrogen production, carbon valorization, and synthetic fuels. Konist stressed the need to think in terms of an integrated energy system and to find better ways to plan and balance renewable energy solutions.

Jaano Haidla, CEO of Graanul Invest, confirmed that the company currently valorizes mainly residues from the wood industry, but once higher value-added biobased solutions become economically viable, they are ready to redirect resources toward chemical valorization. At the same time, he emphasized that existing systems cannot simply be shut down before new solutions are operational: “It makes no sense to close the old well before the new one is ready.”

Lauri Raid, Head of Bioproduct Development at VKG Fiber, pointed out that various sectors – valorization projects, ports, wood fuel producers, and energy producers – are competing for the same wood raw material. For Raid, the critical question is how many biorefineries Estonia can sustain without exhausting the available raw materials in a sustainable way.

Professor Jaan Kers from TalTech, who moderated the discussion, asked the panel what needs to change to attract more investment into bioproduct manufacturing in Estonia.

The participants concluded that the bioproduct sector needs strong biotechnology infrastructure, clean and affordable electricity, and a qualified workforce to develop further. Although biotechnology is taught in both Tallinn and Tartu, the number of specialists entering the labor market remains low. The discussion also highlighted high energy prices and expensive raw materials as major obstacles to the broader adoption of biobased solutions in Estonia.

The development of biotechnology and synthetic biology opens up new opportunities for Estonia’s forestry sector, potentially leading to greater economic value and more sustainable resource use. However, existing energy production and current wood use cannot be completely sidelined – the transition must be carefully planned and supported by appropriate infrastructure and policies. The key question is whether we will use our natural resources more wisely in the future or continue to simply burn them.

The panellists agreed that the bioproduct sector needs strong biotechnology infrastructure, clean and affordable electricity, and a skilled workforce to develop further. Photo: Arno Mikkor

Future fuel – with or without carbon?

The shipping sector contributes approximately 3% of global greenhouse gas emissions, and this share has been steadily increasing. Is it even possible to achieve carbon neutrality in this field? This was the question addressed by Rene Pärt, Head of Business Development and Member of the Management Board at the Port of Tallinn.

Today, the shipping sector consumes around 300 million tonnes of fuel annually, over 95% of which is fossil fuels. The most common green alternative currently in use is liquefied natural gas (LNG), which is seen as a transitional fuel. However, methanol, ammonia, and hydrogen are also being seriously considered. “Methanol is easier to handle than ammonia, whereas hydrogen requires large storage capacities, making it more suitable for short routes and ferries,” explained Rene Pärt.

Internationally, targets have been set to reduce the carbon intensity of shipping – by 40% by 2030, 70% by 2040, and to achieve net-zero emissions by 2050. Progress in the alternative fuels market has been slow, and so far, the sector’s main focus has remained on LNG as a transitional solution.

Several port-based projects focusing on alternative fuels are underway in Estonia. At Muuga Harbour, green methanol operations and services for diesel-powered container ships have begun, while cruise ships have already submitted inquiries for green methanol bunkering starting from 2027. Additionally, an LNG terminal is planned for Muuga, with completion expected between 2027 and 2030. In parallel, alternative energy production capabilities are being developed at the South Port of Paldiski.

Rene Pärt, Head of Business Development and Member of the Management Board at the Port of Tallinn. Photo: Arno Mikkor

In the panel discussion following the presentation, participants included TalTech Professor Allan Niidu, University of Tartu Associate Professor Rasmus Palm, and Rene Pärt. The conversation was moderated by Eveliis Vaaks, editor of Trialog.

Palm highlighted the bottlenecks in the development of hydrogen technology, emphasizing that using hydrogen under pressure or in liquefied form remains technologically challenging – new solutions are needed. Niidu added that future fuels should either be biomass-based or CO₂-neutral. “Carbon valorization is the next logical step, but progress is hindered by high production costs and an uncertain investment environment,” he noted.

Pärt also pointed to the potential of electrification but underlined the challenges it presents: “A single cruise ship can consume as much electricity as the entire city of Paide – this puts a tremendous strain on the energy system.” The discussion emphasized that Estonia’s ports should evolve into green energy hubs, and it is critical to make swift decisions to avoid falling behind in the international market.

Will the fuel of the future be completely carbon-free? The answer depends on technological breakthroughs, regulatory frameworks, and, above all, the investments made in the sector.

Will the fuel of the future be completely carbon-free? The answer depends on technological breakthroughs, regulatory frameworks, and, above all, investments made within the sector. Photo: Arno Mikkor