Researchers at TalTech’s Department of Materials and Environmental Technology are dedicated to creating smart, energy-efficient environments and finding new applications for natural resources. The Inorganic Materials Research Lab, where experienced scientist Mai Uibu works, focuses on the properties and reuse of industrial waste, including oil shale ash.

In recent years, this research has been practically applied through close collaboration with Ragn-Sells’ subsidiary, R-S OSA Service OÜ, which aims to develop innovative solutions from deposited oil shale ash.

“Our main collaboration with Ragn-Sells began through the Smart Specialization project of the Estonian Business and Innovation Agency (EIS), and we have been partners in various development projects ever since,” Uibu explained. In addition to her role at TalTech, she also works part-time at R-S OSA Service OÜ, where she coordinates and advises on laboratory testing.

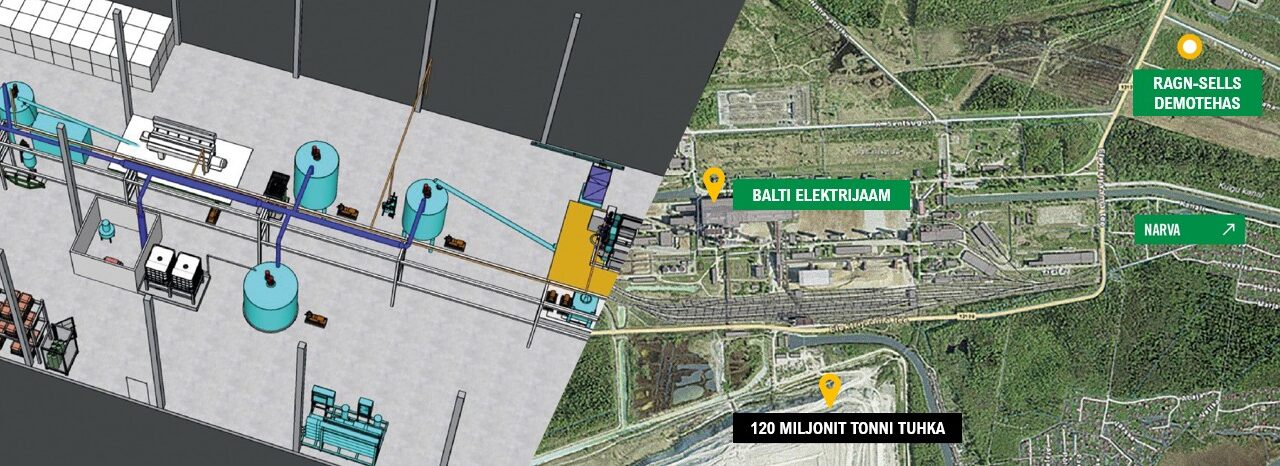

The goal is to open the demo plant this year at the Narva Industrial Park. Photo: Mai Uibu

Oil shale ash – from problem to resource

The main goal of R-S OSA Service OÜ is to develop a feasible and cost-effective way to reuse oil shale ash heaps. To achieve this, they are developing an innovative technology that allows for the extraction of precipitated calcium carbonate (PCC) from oil shale ash. This calcium-rich material can be processed through a two-step ammonium salt-based extraction method to produce high-purity PCC.

The applications of precipitated calcium carbonate are vast—it is used in construction materials, industrial products, and even in the food industry as a filler and colouring agent. Its suitability depends on factors like particle size, morphology, and purity.

A key challenge is working with deposited oil shale ash. “We initially started research with fresh oil shale ash, but we soon had to shift focus to deposited ash heaps, as oil shale-based electricity production is likely a thing of the past—meaning fresh ash will no longer be available in the future,” explained Mai Uibu.

This shift required new solutions, as deposited ash is significantly more challenging to process. Its calcium compound content varies layer by layer, requiring additional pre-treatment. “Fresh ash from power plants already has a suitable particle size, but deposited ash must first be mined, sorted, and ground before it can be used,” she added.

A number of Estonian companies are currently developing industries aimed at extracting calcium carbonate from oil shale waste rock or using oil shale kerogen in the fine chemical industry. One such company is R-S OSA Service OÜ, whose main objective is to find an accessible and cost-effective method for reusing oil shale ash heaps. To this end, they are developing an innovative technology that makes it possible to obtain precipitated calcium carbonate from oil shale ash. Photo: Wikipedia

A unique approach in Europe

Mai Uibu emphasizes that the R-S OSA Service OÜ oil shale ash project is one-of-a-kind in Europe. While various methods for producing precipitated calcium carbonate (PCC) from waste materials have been researched worldwide, no one has yet built a pilot plant. “We are true pioneers in this field.”

So far, the collaboration has been highly successful. Laboratory tests and initial pilot projects have shown promising results, and preparations for building the pilot plant are underway. According to Uibu, the foundation stone has already been laid, and the first pieces of equipment have been ordered. Test operations will begin in the spring of 2026 if all goes as planned.

One of the long-term goals is to expand the technology beyond oil shale ash to other industrial waste materials. “Estonian oil shale ash is quite specific, but a similar approach could be tested with steel slag or paper industry waste.”

Studies estimate that Estonia has around 600 million tons of deposited oil shale ash, meaning there will be material to process for decades, even after oil shale use ends. “Our goal is not just to eliminate these mountains but to reduce the need for new resource extraction by utilizing what already exists,” said Uibu.

Beyond calcium carbonate, the research team is also exploring ways to extract valuable elements from the ash. Some of these elements are classified as critical raw materials, making TalTech and Ragn-Sells’ collaboration highly valuable for Estonia and Europe’s economic development. By smartly repurposing oil shale ash heaps as material banks, Estonia’s Ida-Viru County could become a new circular economy hub—boosting the region’s industrial sector, creating local jobs, and generating economic benefits for all of Estonia.

“Our goal is not just to eliminate these mountains but to reduce the need for new resource extraction by utilizing what already exists.”

Bold ideas drive progress

Mai Uibu emphasizes that reducing environmental impact is a key priority for the project. “Oil shale ash still accounts for a significant share of Estonia’s waste production. Utilizing deposited ash would reduce the need for new resource extraction and promote the circular economy.”

“Oil shale ash still accounts for a significant share of Estonia’s waste production. Utilizing deposited ash would reduce the need for new resource extraction and promote the circular economy.”

While the project has made significant progress, Uibu acknowledges that many challenges remain. “The calcium carbonate production process must be efficient and economically viable. Additionally, we need to ensure that the final product meets all industry quality standards.”

According to Uibu, gaps in legislation are another hurdle for circular economy projects. “For example, we lack clear regulations for CO₂ storage and reuse. Open communication and stakeholder collaboration are essential because sustainable development is ultimately a shared goal.”

If the project succeeds, it could pave the way for new high-value collaborations and strengthen Estonia’s reputation as a hub for innovation and environmentally friendly solutions.