Raid began his studies at TalTech in the field of product development and manufacturing technology but soon shifted to mechatronics, realizing that mechanical engineering alone couldn’t make things work entirely. “Mechatronics engineers seemed like incredibly competent people who understood not only mechanics but also electronics and software,” he explained.

During his studies, Raid spent a year in Munich through the Erasmus program, where he was amazed by the extensive experience of the professors – many of whom had worked in leading automotive companies such as Audi, BMW, and Ford before becoming educators. In Estonia, specialists with such experience are scarce, simply because there are no large industrial companies here. Moreover, in Germany, production processes and education were closely integrated, providing students with direct exposure to industry realities.

Raid founded his company with Tanel Sildnik in 2014, while they were working in the electronics industry. “In our daily work, we saw many problems arise when starting production lines, and subcontractors were constantly struggling. We realized that we could do these things much better ourselves,” he recalled the company’s early days. Today, Hoob’s customer base is evenly split between Estonian and international markets.

“We saw in our daily work that there were many problems when starting production lines, and subcontractors were constantly struggling. We realized that we could do these things much better ourselves.”

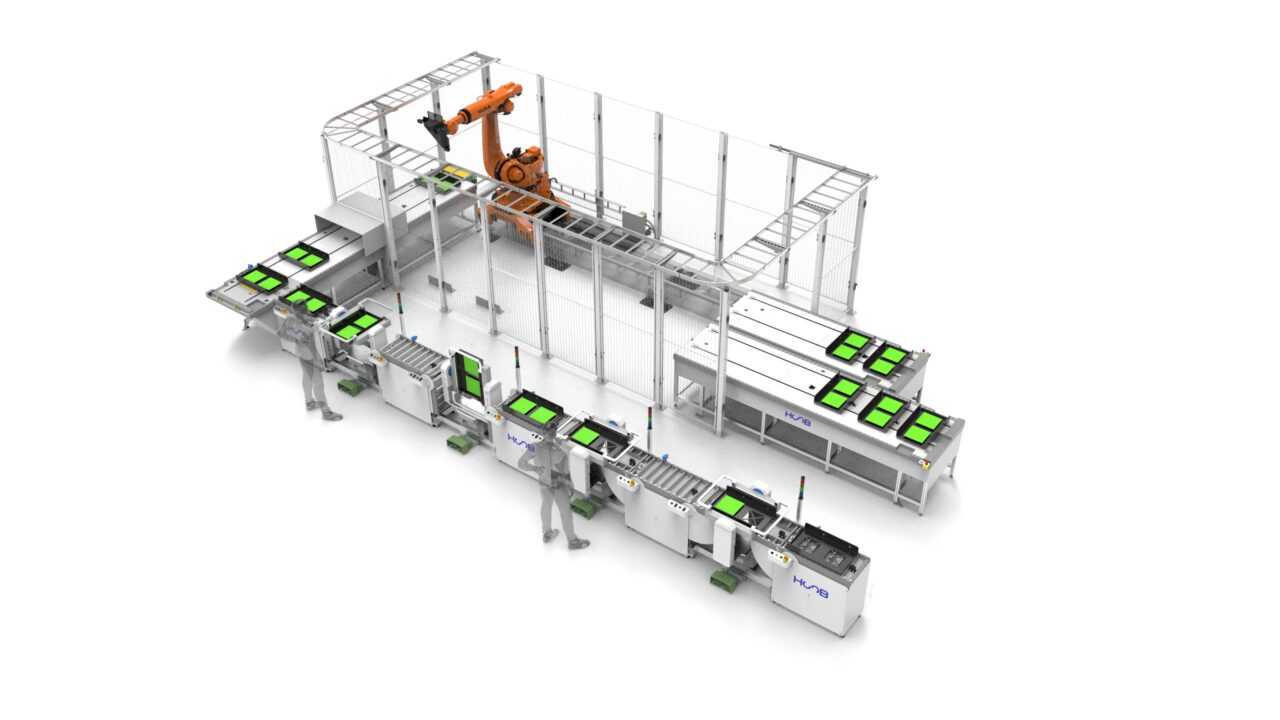

The company produces tailor-made automation solutions according to customer needs. Each product is developed in collaboration with the client, integrating mechatronics, electronics, and software.

Efficiency goes hand in hand with smart solutions – Hoob OÜ's robotic line enables companies to increase production volumes and improve quality while freeing people from routine tasks. Photo: Hoob OÜ

Robots don’t take jobs – they make them smarter

While one of the goals of automation and robotics is to reduce costs, Raid debunks the myth that robots take away jobs from people. “I haven’t seen a single company lay off employees due to automation in the past ten years. Instead, they are given new tasks, which are often even more interesting and valuable,” Raid confirmed. According to him, Estonia’s most pressing problem is not job losses due to automation but rather a labor shortage.

Automation brings changes to the industry that increase the demand for smarter and more versatile employees. This means there is a growing need for experts who can manage, set up, and maintain production lines. Employees who understand machines and systems and can skillfully work with them are especially valued.

“I haven’t seen a single company lay off employees due to automation in the past ten years. Instead, they are given new tasks, which are often even more interesting and valuable.”

Intelligence and flexibility – the key to survival for Estonian industry

Raid explained that the current trend in automation is making robotic systems increasingly intelligent – robots now offer, for example, machine vision and are better integrated with other software systems, enabling faster reconfiguration and greater flexibility in production.

In addition to machine vision and improved integration, robots themselves are becoming increasingly autonomous. “Previously, a robot was just an accurate and fast machine that did exactly what it was told, but now they have the ability to adapt and learn,” Raid explained. This means that robots can respond to changing production conditions in real-time, adjust their work to different products, and even detect potential failures before they disrupt production. Such intelligent systems allow Estonian companies to keep their production flexible and quickly respond to changing market needs.

Based on his daily experience, Raid has noticed that small and medium-sized Estonian companies have become increasingly bold in automating their production processes in recent years. While this was once mainly the domain of large foreign companies, even smaller factories now see automation as a crucial competitive advantage. “For Estonian industry, it’s essentially a matter of survival.”

Raid believes that the competitive advantage of Estonian companies lies in their flexibility and ability to work with small production volumes. Since achieving large-scale production is challenging, local companies focus on intelligence and flexibility to reduce input costs and maintain competitiveness.

People and robots hand in hand – automation accelerates production, but human skills and knowledge remain irreplaceable. Photo: Hoob OÜ

Automation as an investment towards the future

Raid views the future of automation in Estonia with optimism. Despite the rapid pace of technological advancement, with some solutions becoming cheaper in a few years, he advises against postponing necessary decisions. The right time to automate is when a company sees a clear business benefit. “There’s no point in delaying automation, hoping that cheaper and better solutions will come later. This field is constantly evolving. It should be approached like any other investment – consider where the highest productivity and benefits lie, and act accordingly,” Raid emphasized.

“There’s no point in delaying automation, hoping that cheaper and better solutions will come later. This field is constantly evolving. It should be approached like any other investment – consider where the highest productivity and benefits lie, and act accordingly.”

According to Raid, a well-designed automation solution pays for itself quickly and can operate efficiently for at least ten years. Moreover, these systems can be updated to meet future needs as they arise.

Hoob OÜ also maintains close cooperation with universities, offering practical tasks in the field of robotics to students, thereby fostering talent in the sector. In Raid’s view, the industry needs more people capable of working with both their hands and minds. “There are fewer and fewer people with golden hands and bright minds. And it is precisely these people that are in increasing demand,” he concluded.