“The goal is not to replace humans but to create intelligent artificial companions that make life easier and safer,” said Professor Vladimir Kuts, head of TalTech’s Industrial Virtual and Augmented Reality Laboratory.

TalTech’s Industrial Virtual and Augmented Reality Laboratory offers an impressively diverse range of services. The lab enables the integration of digital twins, the implementation of robotic systems, and the development of virtual and augmented reality applications tailored to specific situations and clients. These services are not limited to the industrial sector – solutions are created broadly and flexibly for various fields.

When a humanoid robot moves in

A groundbreaking project is taking shape in Kuts’ lab, aiming to integrate humanoid robots – robots designed in human form – into our daily lives. In the future, the goal is to support people with limited functional abilities.

Initially, these robots will not be tested in actual users’ homes. Instead, the trials will be conducted with the staff and students of Tallinn Health Care College. Kuts emphasizes the importance of improving the quality of life for people whose physical capabilities are limited due to illness, age, or other factors. “According to the current plan, the robots will be 1.35 meters tall, capable of moving their arms and legs, responding to their environment, and most importantly – continuously learning.”

A key aspect of this project is that the robots are not directly programmed; instead, their skills develop in virtual environments. Rather than writing code directly, the robots learn through machine learning – a branch of artificial intelligence where the system performs thousands of trials and improves itself based on the outcomes. The virtual environment offers the robot’s “brain” endless opportunities for practice: it can test various movements, timings, and reactions, analyze them, and optimize them before transferring the skills to the robot’s physical body.

This approach ensures rapid development without wasting physical machines or taking unnecessary risks. “Imagine a person whose hands do not function well putting on virtual reality glasses and special gloves, controlling the robot’s body instead of their own. The robot first assesses how successfully the person performs their physiotherapy exercises – only then does it lend a helping hand for other tasks. This is about collaboration, not replacement.”

“Imagine a person whose hands do not function well putting on virtual reality glasses and special gloves, controlling the robot’s body instead of their own. The robot first assesses how successfully the person performs their physiotherapy exercises – only then does it lend a helping hand for other tasks. This is about collaboration, not replacement.”

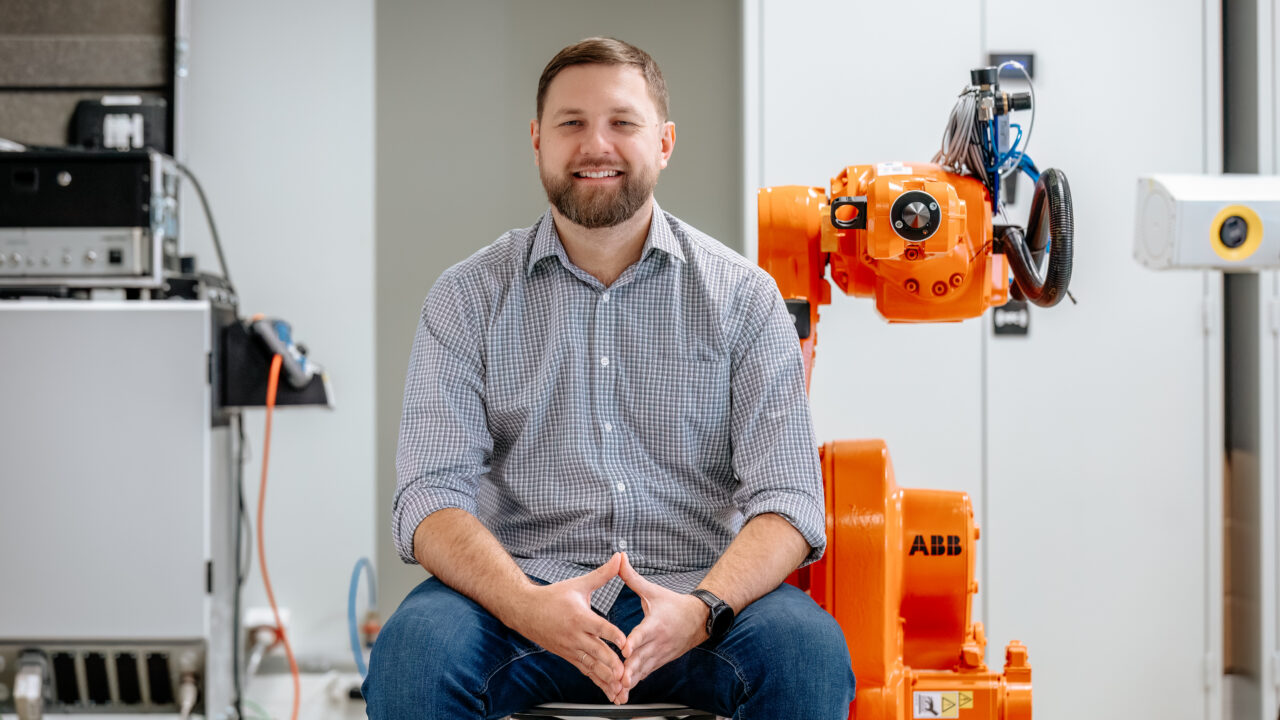

TalTech's Virtual and Augmented Reality Laboratory – an innovative environment where virtual and augmented reality solutions meet machine learning and robotics, transforming ideas into practical applications. Photo: Vladimir Kuts

Virtual factories and digital twins

While humanoid robots promise a revolution in healthcare and homes, an even greater transformation is taking place in industry. Technological advancements no longer just mean robots on the assembly line – they also mean that an entire factory can be built and tested in a virtual space before any machine is put to work in the real world.

This is made possible by digital twin technology. The entire production line – robots, conveyors, components, and processes – is first created in a virtual environment. Here, it is possible to test how different machines interact, what obstacles may arise, and how to solve them. “Physical machines may be far apart, but in the virtual world, they come together and work as a single system. This allows us to see even before purchasing the equipment whether they are compatible, how they behave, and whether it is even worth integrating them.”

“Physical machines may be far apart, but in the virtual world, they come together and work as a single system. This allows us to see even before purchasing the equipment whether they are compatible, how they behave, and whether it is even worth integrating them.”

If any machine or movement does not work efficiently in the virtual environment, adjustments are made, retested, and only then are the improvements applied to the real factory. This approach saves money, time, and resources. “There is no longer a need to waste expensive machines or human hours just to discover later that something doesn’t work,” emphasized Kuts.

Machine learning allows virtual factories to increasingly predict which combinations of equipment work efficiently and suggest optimal settings. “It’s a continuous feedback loop – virtual machines learn, provide information, changes are made based on that, and we gradually move towards smarter manufacturing,” Kuts explained.

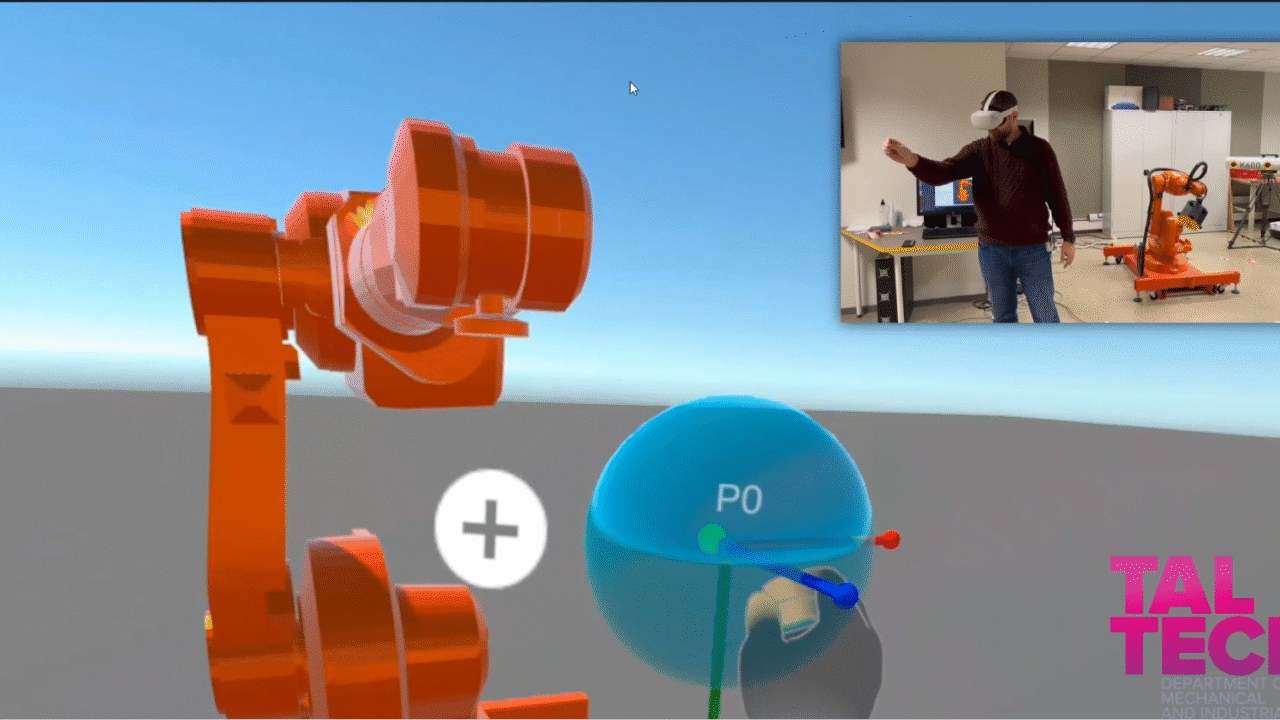

The idea behind this approach is not only to optimize production but also to make the introduction of new equipment smoother and more user-friendly. “We are creating interfaces where a person does not need to know complex programming languages – voice, gesture, or touch-based communication is enough.”

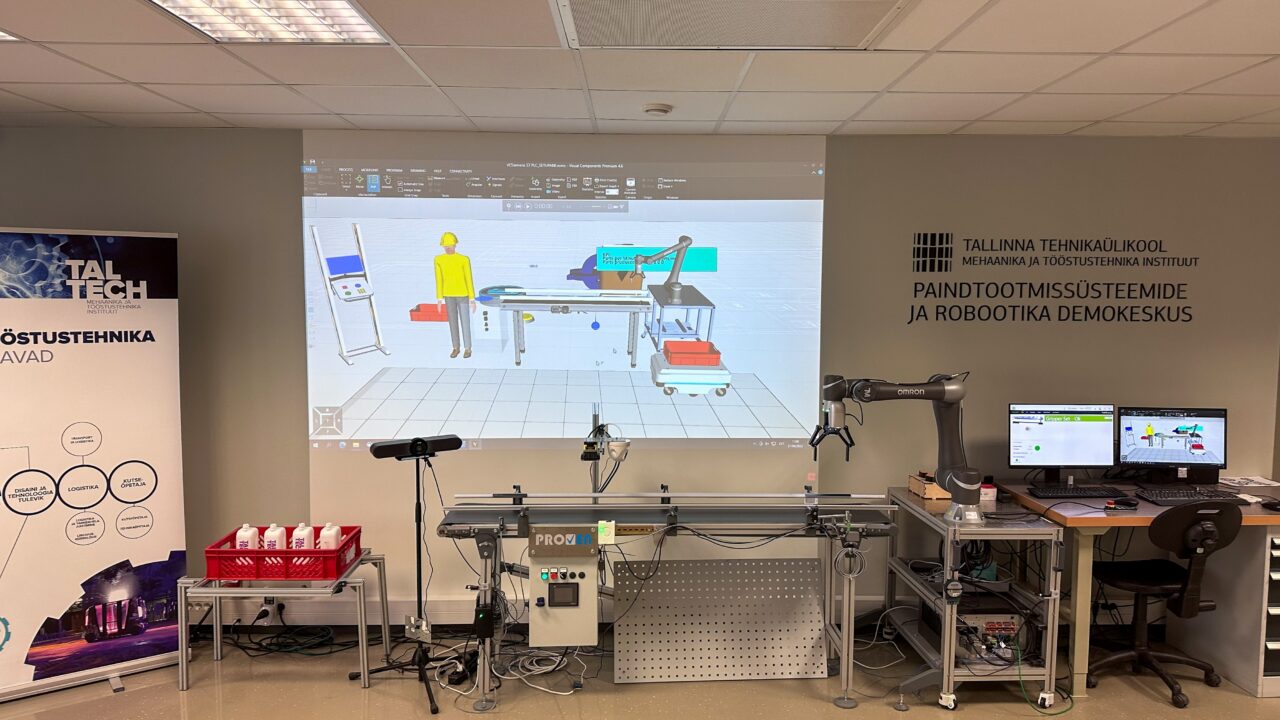

With the help of a virtual environment, a person at TalTech's lab can remotely control equipment and test processes safely and flexibly through a digital twin. Photo: Vladimir Kuts

Humans alongside machines

The rapid advancement of robotics, especially humanoid robots, often raises concerns: will machines take over from humans? Professor Vladimir Kuts dismisses this fear. According to him, humans are not disappearing from industry – their role is simply changing. Instead of performing simple, repetitive tasks, they will take on more complex, decision-making roles. “Industry 4.0 moved people away from routine tasks. Industry 5.0 brings them back – but now they return as creative partners,” he explained.

“Industry 4.0 moved people away from routine tasks. Industry 5.0 brings them back – but now they return as creative partners.”

This shift is particularly important for older workers, who may not easily master complex programming languages. Kuts’ lab is developing interfaces that allow them to work using their experience and logic rather than relying solely on technical skills.

Kuts believes that humans will always be needed – even as robots become smarter and more capable. “Someone has to maintain, teach, and develop these robots. This is not the end of the world, but the beginning of a new era.”

He draws a parallel with robot vacuum cleaners: “If a robot vacuum cleans your home, does that mean you’ve lost a job? No – it means you don’t have to do it yourself and can focus on something more important. The same applies to humanoids.”

In addition to collaborative robots designed for homes and factories, Kuts sees great potential for humanoid robots in future crisis situations. These robots can be sent to places where humans should not go – such as areas with gas leaks or high radiation levels. They can switch tools, operate with precision and speed, all without risking human lives.

An Estonian lab on the world stage

At TalTech’s Virtual Reality Laboratory, work is being done today that is only now making its debut on international conference stages. “I was controlling robots through virtual reality seven years ago. When I saw the same practice being presented as cutting-edge development last year, I realized – we have never been behind in terms of progress. We just haven’t known how to make our expertise visible,” said Professor Vladimir Kuts.

He emphasizes that Estonian researchers are operating at a very high international level, but they often lack the resources and confidence to showcase their work to the world. At the same time, it is impossible to ignore the price competition from China. “Chinese humanoid robots often cost ten times less than European ones. That’s why we use their platforms in our research – not for ideological reasons, but for practical ones.”

Kuts’ message is clear: if Europe wants to have a say in the development of robotics, it must produce more, invest more, and be more visible.

“I was controlling robots through virtual reality seven years ago. When I saw the same practice being presented as cutting-edge development last year, I realized – we have never been behind in terms of progress. We just haven’t known how to make our expertise visible.”

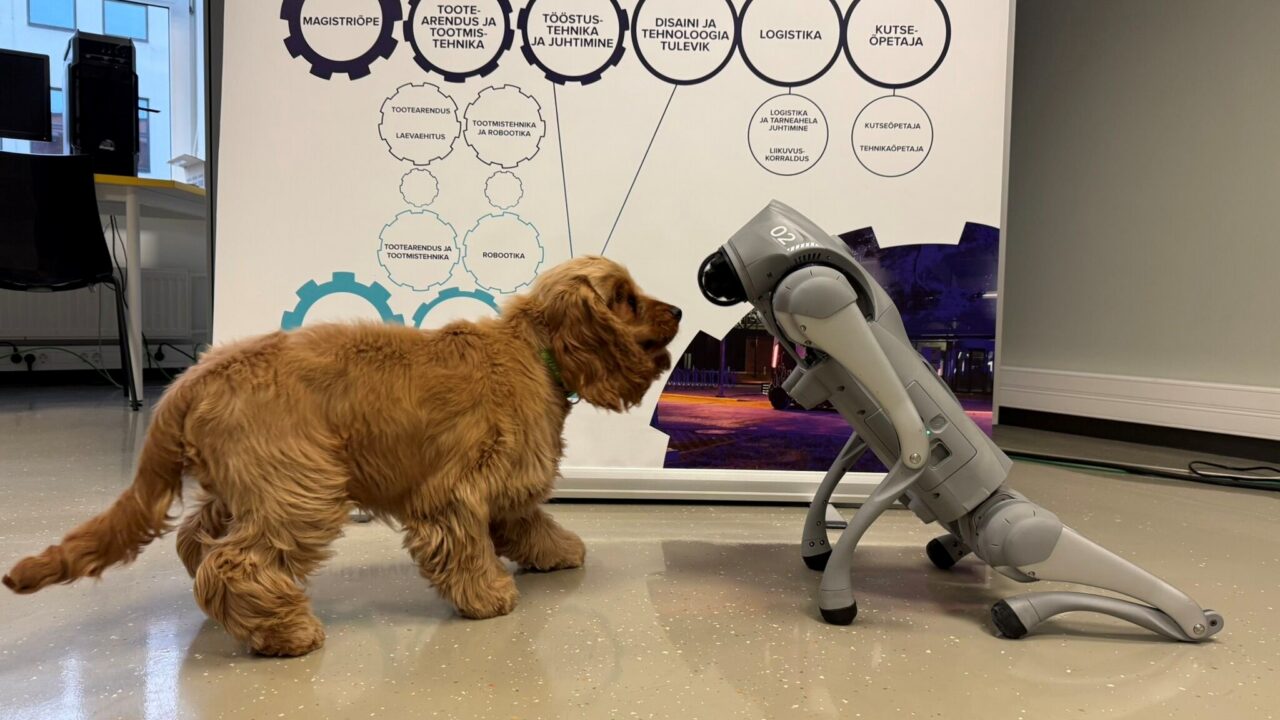

Humanoidrobotid pole enam ulme, vaid reaalsus – samamoodi võivad tulevikus meie igapäevaellu jõuda ka robotkoerad, pakkudes tuge ja seltsi. Foto: Vladimir Kuts

Commentary: Kristo Timberg, CEO of Hansab AS

According to Kristo Timberg, former CEO of Chemi-Pharm, the collaboration with TalTech’s Industrial Virtual and Augmented Reality Laboratory began through a Horizon2020 project focused on the adoption of autonomous intralogistics robots in small and medium-sized manufacturing companies. As Chemi-Pharm was building a new factory at the time, the project’s 3D models were used to create a detailed digital twin, which was later used to simulate processes and assess equipment profitability.

Timberg described the collaboration with the lab as smooth and substantive – the lab’s specialists helped solve problems, developed test environments, and supported the implementation of the digital twin in virtual reality. The result was a versatile learning experience and a valuable contribution to factory development. “With the help of the digital twin, we simulated various work processes in virtual reality, which allowed us to identify several details that we were able to correct during construction – such as narrow pathways or inconvenient storage locations,” Timberg explained.

In his view, the services offered by TalTech’s Industrial Virtual and Augmented Reality Laboratory are most beneficial to small and medium-sized manufacturing companies that want to experiment with new technologies but may not be able to do so independently. “There are probably as many use cases as your imagination allows you to come up with,” Timberg noted